mass flow controller working principle

The accuracy from 20 to 100 of Full Scale FS is 1 of Setpoint relative to the calibration gas. MFCs consist of the following components.

Thermal Mass Flow Meter Working Principle Instrumentationtools

Structure and operating principles.

. Mass flow measurement relates to the amount of heat absorbed by the process gas. Video animation explaining the functions and features of Bronkhorsts MASS-STREAM Mass Flow Meters and Controllers for gases following the direct through fl. Industry-best range of digital mass flow meters and other products to meet widest application needs.

I bought a couple mass flow controllers from eBay to improve the process control of my sputtering chamber. Mass Flow Controller is basically adjusted the gas type and flow rate that specify by customers. All Mass Flow Controller MFCMeter MFM work at a nominal voltage of 24V DC have a low pressure drop and do not require flow conditioning at the inlet or outlet.

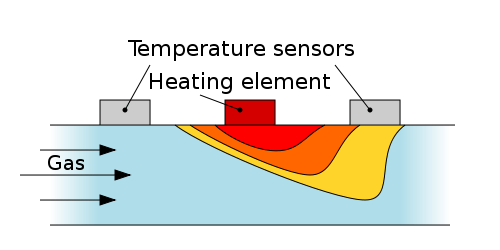

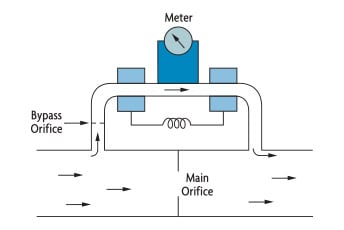

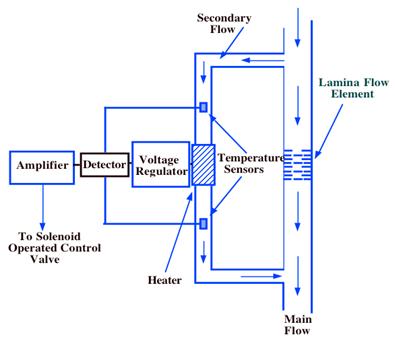

A constant proportion of gas flows through the sensor tube. Volumetric flow measurement is affected by ambient temperature and pressure. MultiFlo technology allows one device to change gas types and ranges without removing the device from the system and improving actual process gas accuracy.

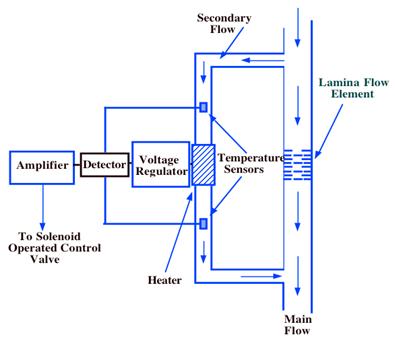

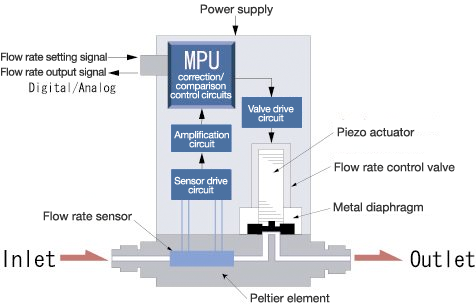

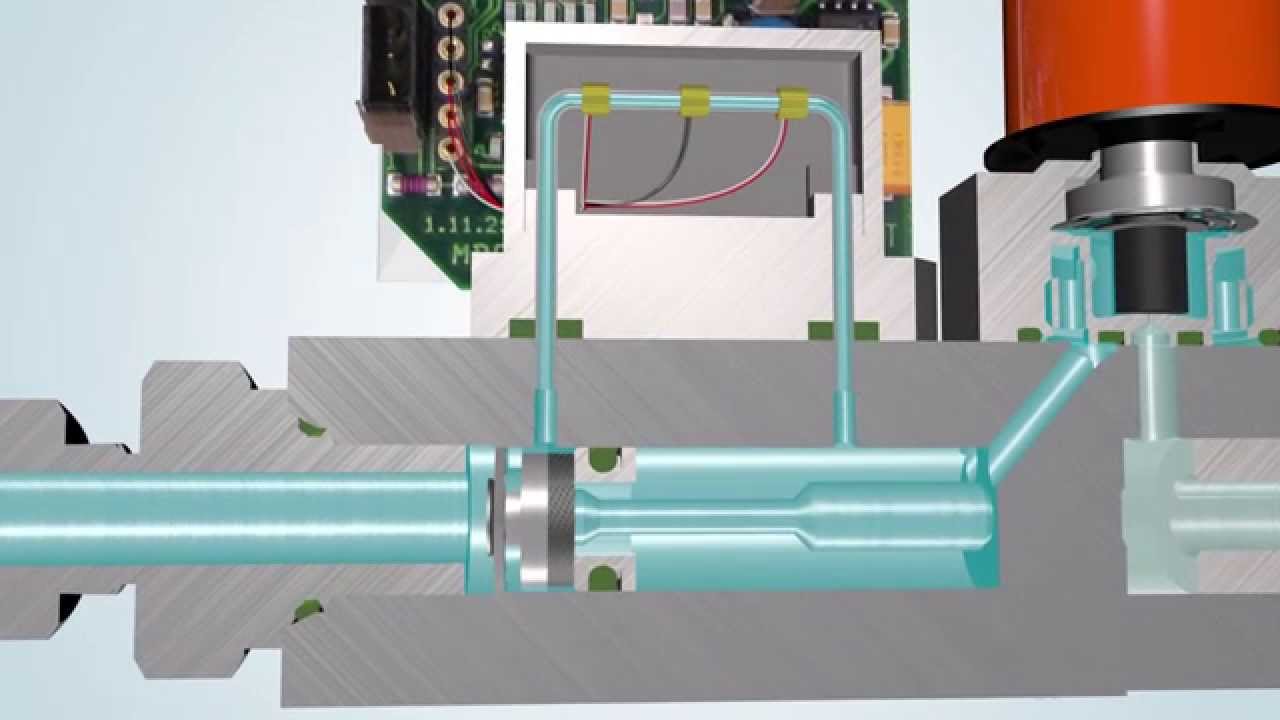

The thermal gas mass flow controller is composed of a flow sensor a diverter channel a flow regulating valve and an amplifier controller. A mass flow controller is designed and calibrated to control a specific type of liquid or gas at a particular range of flow rates. This second mode of operation provides for a much higher meter rangeability.

The MFC can be given a setpoint from 0 to 100 of its full scale range but is typically operated in the 10 to 90 of full scale where the best accuracy is. 2 In büS-modus up 32 MFCMFM can be connected to a system control unit SCU eg. A mass flow controller automatically regulates the flow rate according to a set flow rate sent as an electric signal without being affected by use restraints or variations in gas pressure.

These MFCs are much better suited than a needle v. A mass flow controller MFC is a device used to measure and control the flow of liquids and gases. Flow rates can be roughly split into two kinds.

All Mass Flow Controllers from Bürkert are compact devices that control the mass flow of gases. All Mass Flow Controller MFCMeter MFM work at a nominal voltage of 24V DC have a low pressure drop and do not require flow conditioning at the inlet or outlet. Both methods are based on the principle that higher velocity flows result in a more significant cooling effect as.

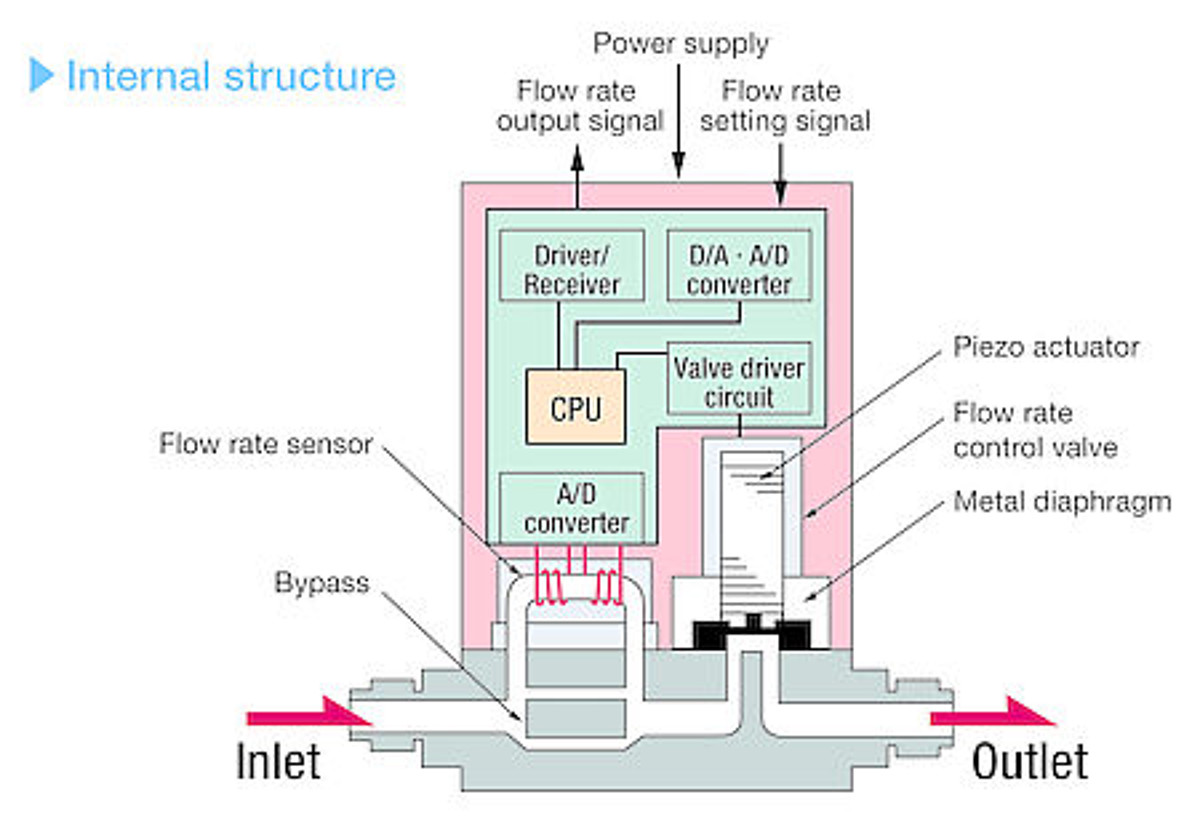

Gas mass flow controller working principle. These mass flow controllers have a flow rate measurement section that includes a sensor bypass flow rate control valve and special circuitry. For setpoints between 2 and 20 MFC Mass Flow Devices have an accuracy of 02 FS.

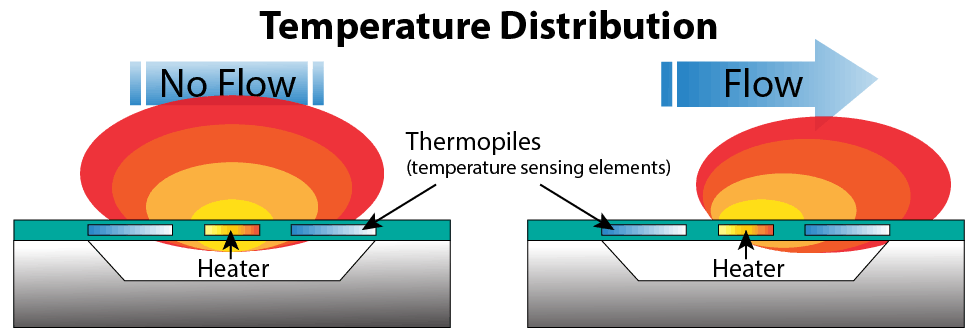

Both gas and liquid mass flow instruments incorporate a significant time constant effectively a delay in the range of 5 seconds in the flow signal to dampen out spurious signals. The flow signal measured by the sensor heating bridge is sent to the amplifier for amplification. The gas flow sensor uses the principle of capillary heat transfer thermocalorimetry to measure the mass flow of gas without temperature and pressure compensation.

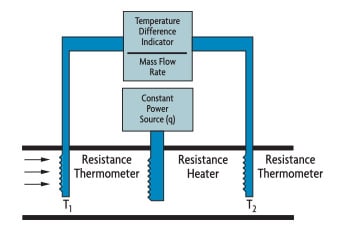

As a result of filter dirt. The sensor tube is heated by applying an electric current to the elements. The thermal Mass Flow Meter or Controller is capable of providing direct measurement of mass flow as opposed to most other methods that measure volumetric flow and require separate measurements for temperature and pressure in order to calculate density and ultimately the mass flow.

The MFC measures the mass flow rate of a gas and controls the flow rate according to a given setpoint. The mass flow controller valve is made up of. The sensor measures the mass flow rate of the gas.

This flow meter has two operating modes. It consists of a small bore tube with two resistance-thermometer elements wound around the outside of the tube. In case using the other gases Calculated value by CF and the actual flow rate may not match.

In this video from Sierra youll learn the theory and working principles of thermal dispersion mass flow technology that is used in our gas flow meters. The relationship between mass flow and volumetric flow is as follows. The gas is input from an Inlet joint and is divided so that it flows over both the flow rate sensor and a bypass.

MultiFlo is offered for use with thermal thermal mass or flow sensors. They control a preset flow rate reference value regardless of disturbance variables such as pressure fluctuations or temporary occurring flow resistances eg. The other mode holds the temperature difference constant and measures the amount of electricity needed to maintain it.

Model 261 Thermal Mass Flow Controllers Parker Model 261 Mass Flow Controllers MFC incorporate an operating principle based on the thermodynamic properties of the process gas being measured. Operating Principle The heart of a mass flow controller is a thermal sensor. The amount of heat the gas absorbs is determined by the gas molecular.

In addition it may cause abnormal operation or abnormal flow by the differences in the physical properties values of the gas. The mass flow is measured as a function of the difference between the temperature of the heated sensor and the flow stream. So our thermalcalorimetric measurement technique utilises this principle i.

Mass flow controllers utilize a PID Proportional Integral Derivative control loop to maintain a steady flow rate coming out of the integrated control valve. Volumetric flow and mass flow. One measures the mass flow by keeping the electric power input constant and detecting the temperature rise.

MKS mass flow controllers have thermal and pressure based sensor technologies analog and digital communication and metal or elastomer seals. DPC precision digital mass flow controllers incorporate multi-gas functionalities allowing users on site to select up to 30 different gases locally via optional OLEDJoystick interface remotely via the RS232RS485 interface or optional Modbus RTU interface. Working principle of thermal Mass Flow Meters Controllers.

Industrial thermal mass flow meters also known as thermal dispersion or immersible thermal mass flowmeters comprise a family of instruments for precision measurement of total mass flow rate equation of a fluid primarily. Mass Flow Rate Density x Volumetric Flow Rate Although volumetric flow under nominal conditions may be accurately calculated the process conditions and fluid properties can vary sufficiently such that it is questionable if the measured volumetric flow rate or derived using velocity represents the. A motive force electromagnetic thermal piezo-electric motor-driven etc a resistive force spring diaphragm etc a variable flow restriction orifice-poppet orifice-balletc The motive force is activated by the control circuitry to act against the resistive force to vary the flow restriction.

The mass flow meter uses the principle of capillary heat transfer thermometry to measure the mass flow of gas without temperature and pressure compensation. COVID-19 Coronavirus Information Travel health safety precautions for MKS employees partners.

Laminar Flow Element Lfe For Flow Meters Bronkhorst

Thermal Mass Flow Sensors What Is Their Working Principle

Mass Flow Controller Mfc Working Principle Bronkhorst

Mass Flow Controller C F Fcon Co Ltd

Horiba Fluid Measurement Control Mass Flow Controller

Select The Best Flow Meter For Your Application Bronkhorst

File Mass Flow Controller Jpg Solidswiki

How A Mass Flow Controller Works Youtube

Mass Stream Thermal Mass Flow Controller Principle Of Operation Youtube

Mass Flow Controller C F Fcon Co Ltd

Horiba Fluid Measurement Control Mass Flow Controller

Thermal Mass Flow Sensors What Is Their Working Principle

![]()

Schematic Of Flow Control Schemes For Mass Flow Controllers Used In The Download Scientific Diagram

Comparing Gas Flow Instrument Technologies Alicat Scientific

Mass Flow Controller Mfc Working Principle Bronkhorst

.jpg)